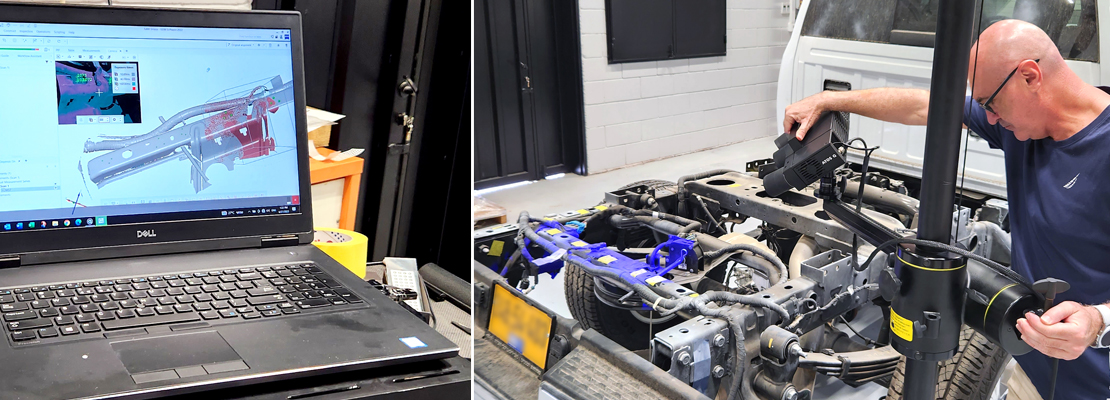

New at Aran – Aran’s Development and Manufacturing Department recently upgraded to the new GOM ATOS Q, a 3D scanning camera from ZEISS, along with the GOM software for data processing.

The advanced technology of the GOM ATOS Q offers unique and innovative capabilities in the manufacturing process and quality control. This new system is designed for highly accurate measurements and scanning, suitable for complex parts of various sizes.

One of the most impressive features of the GOM ATOS Q is its ability to scan and measure with exceptional precision, within a range of 3-7 microns. This allows us to achieve remarkable accuracy in correcting tolerances in parts and ensure precise and accurate results. In addition, the system provides data processing capabilities through the GOM software, enabling easy and convenient file generation for engineers.

The new system also serves as a quality control tool in the production lines. Its advanced capability to scan parts manufactured using various technologies allows us to monitor production processes and ensure compliance with required standards.

Furthermore, the system enables us to efficiently and accurately perform reverse engineering processes. We can use the system to create precise 3D scans of existing parts and compare them to the original models or mechanical designs. This process enables us to quickly and accurately identify and rectify manufacturing flaws or errors.

The system is being operated in ARAN by an expert technician with over 10 years of experience.